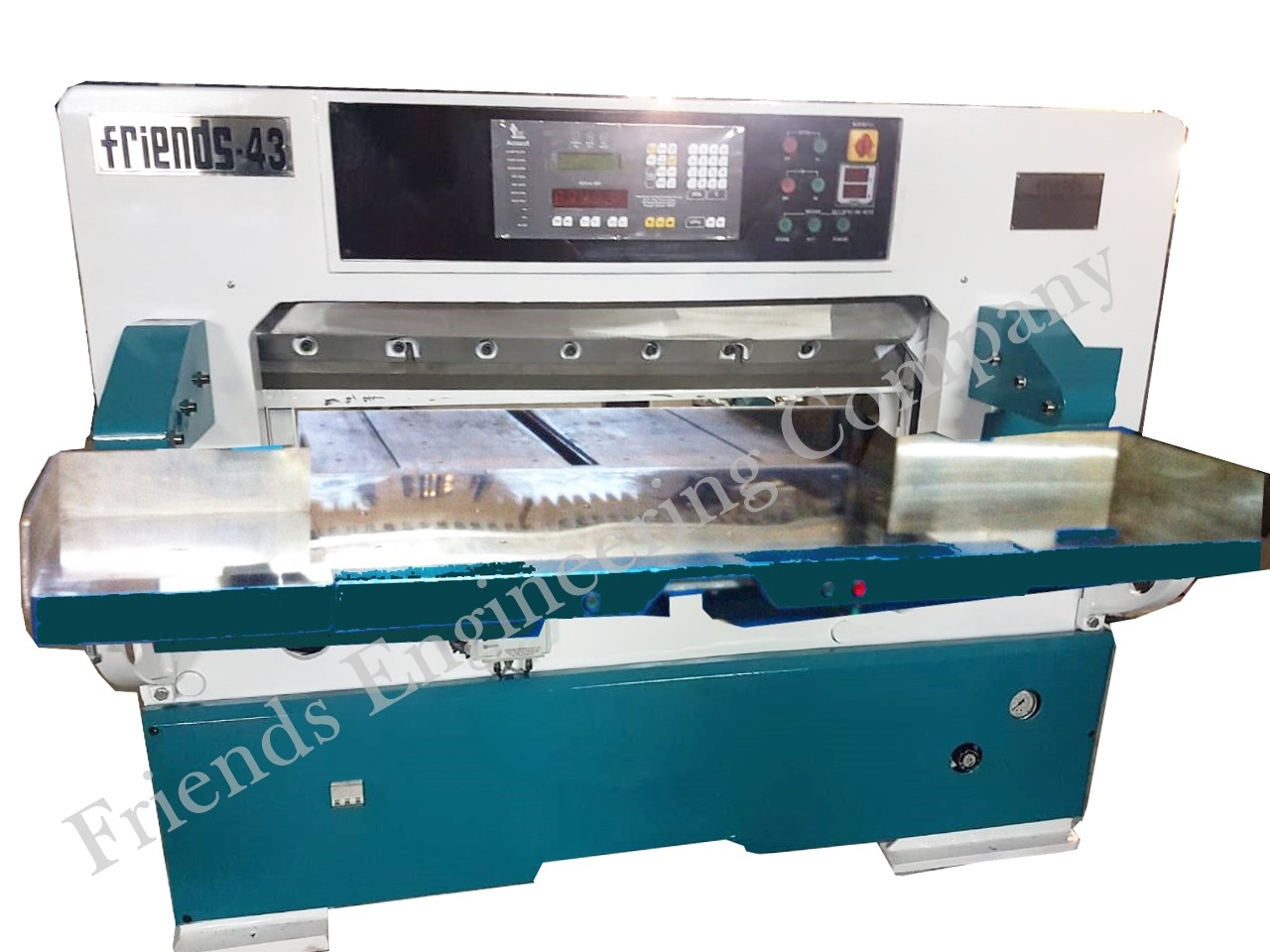

Guillotine Paper Cutting Machine Variant contains everything needed for Accurate Paper Cutting. Auto measurement devices, Programmable Devices, Air Cushion Stainless Steel Bed, Established instinctive administrator direction, Hydraulic Pressure System, huge touch screen, and cycle perception.

Electro-magnetic handle system for most outrageous efficiency and least help. This machine provide programmable adjustable back measure for same similarity with sharp edge. The fast-cutting stroke is incredibly exact, to the sharp edge carrier guides.

This machine is moving along as arranged and definite with its solid arrangement. The Hydraulic Pressing is giving ease to the director of this machine. Security Sensor cells protect the well-being of the administrator against any sort of Accident.

This Machine has an innovative guillotine trimmer with an amazing sizing range. It is a robust solution specifically designed for high-volume cutting operations at one single time. It offers extraordinary precision and efficiency to our productive operations. This machine is one of the main useful tools for companies with paper-cutting needs.

The Guillotine Paper Cutting Machine is a testimony to reliability and performance. Because, it built with strong materials and advanced technology. Engineers can easily operate and fully accomplish its capabilities.

Customers may manage clean and suitable cuts with its sharp blade. A right cuttings helps your business keep up high levels in its results, which uplift product trust and customer happiness. Users may easily trim papers of different sizes and thicknesses to match their unique needs. Every time, the machine produces flawless final products because of its sharp blades, which guarantee accurate and clean cuts.