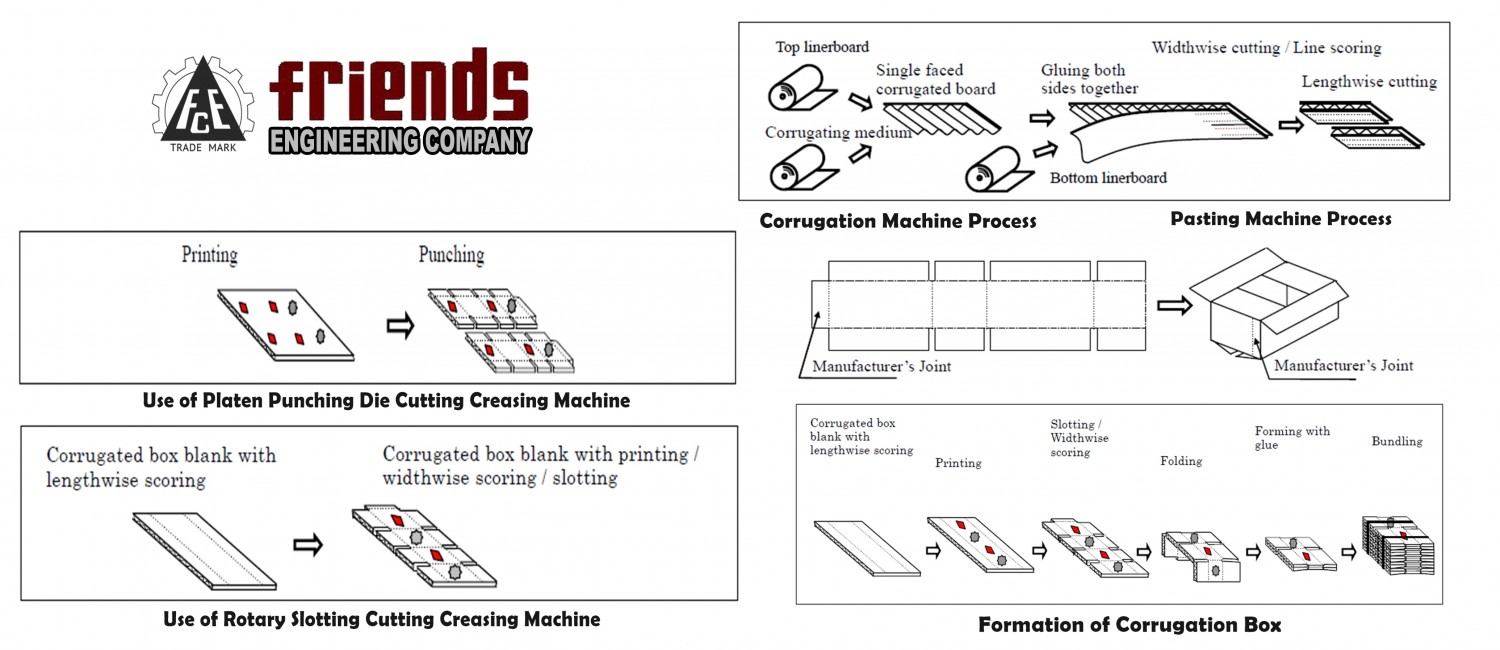

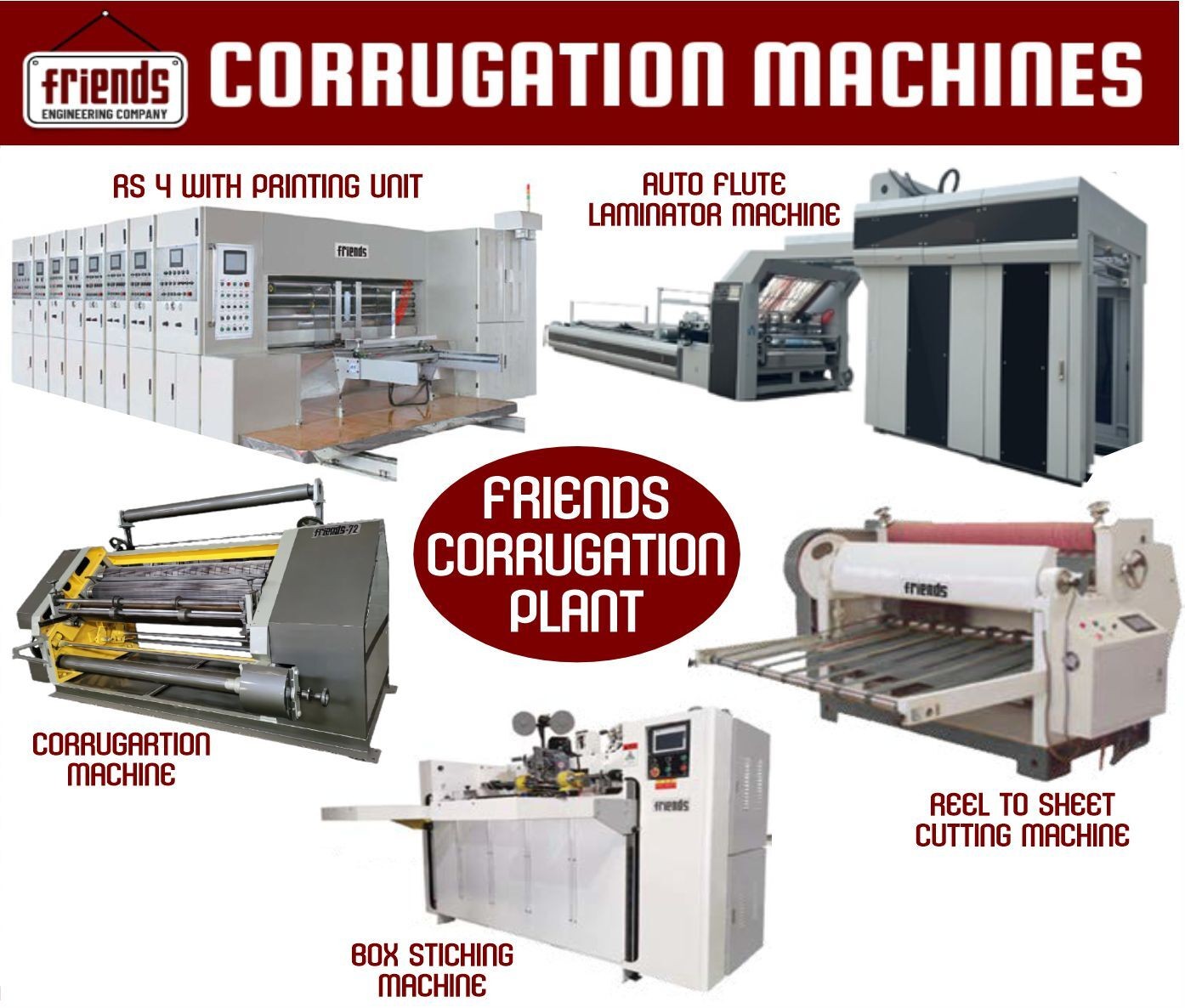

These additional machines are utilised in conjunction with one of the paper corrugation machines to create a fully functional setup plant.

Reel to Sheet Cutting Machine

The perfectly constructed & designed to boom manufacturing and exquisite cutting of corrugated board without damaging the flutes of the board further to straightforward paper. As a exquisite alternative to hand Operated Board reducing machine. it is viable to use the device as an independent unit or it could moreover be attached with the corrugating gadget. If required P.I.V gear area is provided to make sure correct slicing of the sheet as in line with required period and clean to alter and perform. delivery Conveyor Stand is furnished to preserve the Sheets. This tool is designed for immoderate production and instantly lowering of sheets or ply corrugated board with out damaging flutes & liner paper. often, this tool is used as an independent unit for direct and correct sheet cutting.

Features

- Machine is having special characteristic of oil tub equipment machine with oil lubricating pump

- Gadget is outfitted with heavy obligation excel makes P.I.V. tools container.

- Imported chain to regulate the duration of the sheet to be cut with gear Ratio 1:5.

- Machine is driven by means of A.C. frequency pressure with provision for synchronization of speed between Sheet Cutter with Corrugating system.

- With A.C. Motor & Starter.

- Feeding segment with concealed gears.

- Cutting phase with Blade attainable at 4 edges.

- Delivery conveyor with infinite Belts.

- Digital sheet counter.

- Paper cutting ability is two hundred ft in step with minute

Technical Specifications

- This strongly design machine can be used as an impartial unit or can be synchronized to a corrugation system for direct and accurate sheet reducing.

- It minimizes the percentage of wastage.

- PIV tools container is provided for adjusting of sheet to the specified duration from 20" to 80".

- PIV tools box 1:5 ratio shall be provided.

- The machine is robust in layout & in grade casting.

- Robust in construction and clean to operate.

- Nylon sandwich belt shall be provided as a shipping conveyor to hold the sheets out.

- Electric automobiles of three section A/C 1440 RPM / 440 V.

- All shifting parts are covered by using protection guards.

Sheet Pasting Machine

The machine is solely designed and manufactured for the pasting of corrugated sheets of different ply. easy in layout, strong in production, smooth to perform and is confident of ideal operating at some point of non-stop operation. The rolls of the machine are easily completed to make sure even affect on the boards after lamination.

The device is used for applying glue at the tip of the corrugated floor and pasting corrugated sheets of various ply and thickness. This machine is understood for its robust production and ability continuously strolling at even excessive speeds.

Features

- Resistivity to detrimental situations

- Clean operation

- Dimensional accuracy

- Excessive tensile energy

- Sturdiness

Technical Specifications

- The system includes three rolls

- All rolls are grinded, balanced, & hard chromed known as glue pickup roll, pressure roll & health practitioner roll.

- All rolls are installed with ball bearing for clean strolling & longer lifestyles.

- Gum tray is provided to shop the gum built by using H.R / C.R metal Sheet.

- The gum can be launched on the quit of the work through exit factor on the nook of the gum tray

- The system is surely designed, sturdy in creation and clean to function

- Platform is supplied in H.R / C.R steel Sheet.

- Electric powered Motor of 3Phase, A/C 1440 RPM / 440V.

- All transferring components are blanketed via safety defend.

- It assures fault less running throughout non-stop operation.

Flexo printing machine

Flexo printing Machine used for printing on simple Kraft paper Print thru photograph Polymer Stereos Registration for correct Printing appropriate for short Print Run Hand Brake to release the Eccentric pressure controlled transfer of Ink. available in option of single color unit, Double coloration Unit and Tripple color unit.

Features

- Auto stop for safe smash (Sensor Attachments)

- Helical equipment for smooth walking and long life.

- All rolls are dynamically balanced and tough chrome plated.

- Quick Changeover of plate cylinder to reduce the down time.

Technical Specifications:

- Horizontal: +/-15mm with locking

- Vertical: +/-l5mm

- Ahead inching facility (walking)

- Automobile prevent for safe damage system (Sensor Attachments)

- Impact rollers and Anilox rollers are dynamically balanced,

- Floor and tough chrome plated

- Helical gears for reduced play, easy motion and long life

- Guide Registration changes

Platen Punching Die Cutting Machine

We originate our first-class Friends Die Cutting and Creasing Machine it truly is ready with Electro-Magnetic Clutch and Brake for straightforward operations. Manufactured from the most effective excellent uncooked materials, hierarchical factors, this Die Cutting and creasing Machine is successful and designed for Die-Cutting, Creasing, Punching and Embossing Job on varied product like Paper, Card Board, cardboard, Fiber Board, Vinyl, Foam, Rubber, Leather, Masonite, Cork Sheets, affixed Boxes, Advertising Cut out, Jigsaw Puzzles, Labels and some distance extra. Additionally to the existing, the Die Cutting and creasing Machine that we offer complies with the set business standards. Our valued shoppers will avail the Platen Die Punching Machine manufacturing unit-made in numerous sizes as per their

desires.

Features:

- Totally standardized (i.e. all square measure inter-changeable)

- All shafts measure from linear unit Grade steel and pins measure grounded & bushes from Phosphorus Bronze Alloy.

- All bearings measure of SKF/NBC/NACHI solely.

- Fail-safe combination clutch brakes machine with adjustable machine (up to microns).

- The major driving shaft is ready with units of double helical self-lubricated imported polyamide/metal pinion.

- Main electric powered panel (operation and manage) are prepared with Detachable Socket System with international standardized additives i.e. Siemens/L&T/Schneider (France) etc.

- Self diagnostic gadget software with visual indications

- Self diagnostic gadget software with visual indications

- Main flywheel is locked with check-nut machine.

- Fully Automatic Centralized Lubrication System is provided.

- Easy adjustable features of impressions is created through 2 worm gears and eccentric bushes within the cam for left-right and up-down of platen to make the four corners equal.

- Machine has quite silent running and outlook is great with very best quality paint and powder coated fitting.

- “Friends” quickest Platen Opening 87” to supply press Operator adequate Time to feed delivering more productivity.

RS4 (Chain Feeding)

FRIENDS SERIES ROTARY SLOTTING MACHINE commonly known as RS4, is a kind of complete equipment that slotting, slitting, slicing corner, creasing. Its a multi function device with present day features and blessings. its rapid, long lasting and capable to reinforce the production.

Features:

- Semi-automated chain feeding system, facet lay gauge adjust feeding function, make certain feeding appropriately.

- Planet equipment kind motorize take a look at and opposite adjustment in 360°.

- Guide adjusting four box top cutter synchronous (motorize adjusting is option).

- All of shaft precision gring, chrome plated.

- Excessive satisfactory 48CrMo slotting knife with induction hardness.

- Speed variable motor pressure device, speed is adjustable.

- Ready with the image-electricity counter, show manufacturing amount.

- Slotting crease joint movement through hand manage.

Four Bar Rotary Cutting & Creasing Machine

This machine contributes to the packaging industry by trimming and creasing corrugated boards at the same time. The system is easy to operate & sturdy in production. smooth placing is supplied for adjusting, creasing & slicing heads in this machine. degree is supplied for accurate slicing & creasing of sheets. The gadget has strong production and incorporates graded alloy steel knives for smooth reducing. the rate is 300 toes. according to minute and the minimum distance among dies is three inches.

Features:

- The machine is strong in design.

- It incorporates graded alloy metal knives for lengthy life sharpness and clean slicing.

- The creasing dies are not unusual in three and 5 ply, 7 and nine ply and above.

- The shafts of gadget are set up on heavy obligation bearings for clean going for walks noise loose with graded casting gears and nylon gears

- Minimum distance between two dies is three inches.

- All moving elements are included by using safety guards.

Technical Specification:

- The most manufacturing capacities of those machines are 5000 devices.

- Two side gauges are provided for accuracy in slicing and creasing of boards.

- The speed is three hundred feet. per minute and the minimum distance between two dies is three inches.

- Depending upon the thickness of the board (3 ply, 5 ply, 7 ply, nine ply), separate creases are to be used.

- The sheets are piled at the feed table and fed via the device with the aid of hand.

- This is useful for creasing and reducing concurrently.

- The machine is with pairs of shafts.

- The front pair is with reducing dies & rear pair is with creasing die.

- 4 sets of cutting Heads & four units of Creasing Head

Eccentric Slooter Machine

The Eccentric Slotter machine is provided with 4 slotting cutters. The dies are hooked up on an eccentric shaft which causes them to move in an arc in order that the board is slotted in a shearing way. The dies can be moved and slot depth adjusted easily. simple in design, strong in production, smooth to perform and is assured of faultless operating for the duration of continuous operation. This device is used to punch out slots and sewing edge in the corrugated sheets. This operated by hand system is able to slotting wide variety of sheets at a time.

Features:

- The system has 3 slotting & one corner slicing head and gauges are supplied for correct feeding

- 3 slots and one corner cutting is finished simultaneously at the machine.

- It is available in two, three, and five HP capacities, with weights ranging 2200, 2800, 3000, 3200, and 3400.

- The tool rack mechanism included within the gadget allows you to adjust the distance between the slotting and nook reducing heads.

- For accurate feeding, two side gauges are provided.

- The top dies move in an arc, slotting the board in a shearing manner.

- Minimal distance among two dies is 7" corner width is 3.5".

Box Stitching Machine

We provide an completely stitching machine that is suitable for cardboard, corrugated board, the usage of round or flat twine. The corrugated boxes are supposed to be stitched with this system. The coil spring clutch propels the machine. The gadget's pulley rotates at a speed of 350 rpm, allowing us to sew up to 350 pins per minute. The machine has a thickness setter to adjust the space based on the thickness of the board. The parts are standardised, interchangeable, and made of a metallic alloy. This machine is entirely designed for precision and high-quality sewing. This machine is available in both direct and Angular forms.

Features:

- The machine's pulley rotates at a speed of 350 rpm, allowing us to stitch up to 350 pins per minute.

- This system is supposed to sew the corrugated containers.

- The machine is propelled by a coil spring snatch.

- The machine is geared up with thickness setter to regulate the gap depending at the board thickness.

- The elements are standardized and are inter changeable and fabricated from alloy metal.

- This system is solely designed for accuracy and high-quality stitching.

- This device is available in straight / angular / bottom configurations.