Introducing first time in India automatic robot system feeder delivery attachment to be fixed on die-cutting machine.

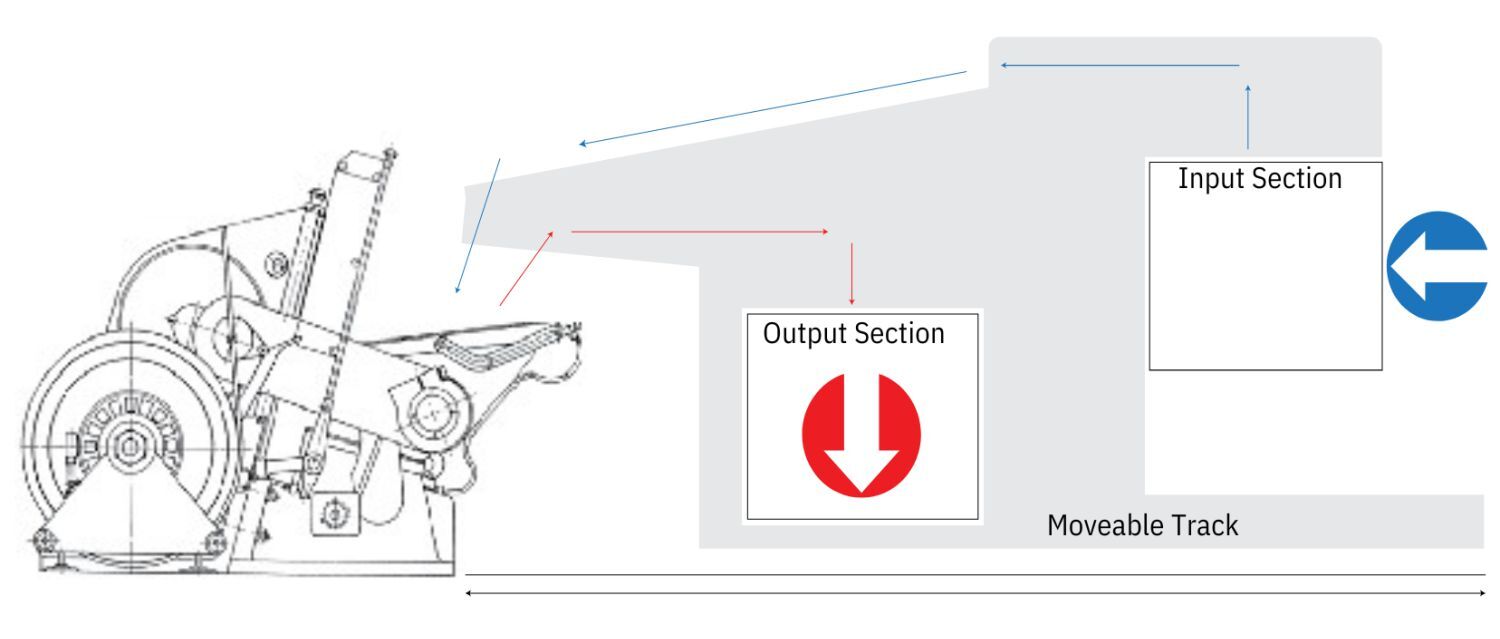

The machine is equipped with multiple electric eye checks to reduce paper waste. The delivery table is equipped with an automatic support device. Precisely, safe and easy to operate.

The front block and side block can be adjusted freely by the paper size. Easy to adjust and precisely. The collection and delivery table both adopt the vacuum inspiration to avoid the problem of the gripper biting no paper.

The device applies to common paperboard, e/b/a corrugated paper, and plastic board. The collection table & delivery table are equipped with automatic support devices. Continuous operation without stopping, works efficiently.

The feeder part is equipped with a tracking device, separating freely when you make a plate. The product has the advantages of low maintenance cost, high speed, convenient operation, saving labor costs, and accurate paper feeding.

The feeder attachment can be attached with our latest model die punching machine to achieve the desired effect like the fully automatic flat die cutting machine. The use of the robotic feeding & delivery system gives the ordinary die-cutting and creasing machine the automatic paper feeding performance of the high-speed machine and is the most ideal feeding mechanism for the die-cutting and creasing machine.