Box Making Machines are the set of Machines used to Manufacture Boxes. Based on Size and Requirements. Globalisation, Industrialization and International Demand and supply chain have resulted in Creating the Demand and Supply of goods from as tiny as Needle to huge Machines. Everything is being Transported from one corner of the world to another. With the Long distance, the problem of safety of Products also arises as the products have to be transported by various mediums such as sea, Air and land.

To prevent the problem of Damage of the products, Packaging plays a Crucial Role and the most common way of Packaging is Box Packaging.

Box Making Machine can be classified into various Categories. To Simplify the Understanding, we have tried our best to Differentiate box Making Machine on the basis of Types of Boxes.

There are Two Kinds of Boxes Used in the Packaging Industry.

- Duplex Boxes

Boxes made of Duplex Sheets / Food Grade Sheets area unit known as as Duplex Boxes. These Sheets area unit readily accessible in the Market. Coated duplex cardboard are durable and thin, more water resistant, usually accustomed create boxes for a range of little merchandise that need high-quality print ability like Agar-batti boxes, Pharmaceutical packaging, Cake Boxes and varied packaging products.

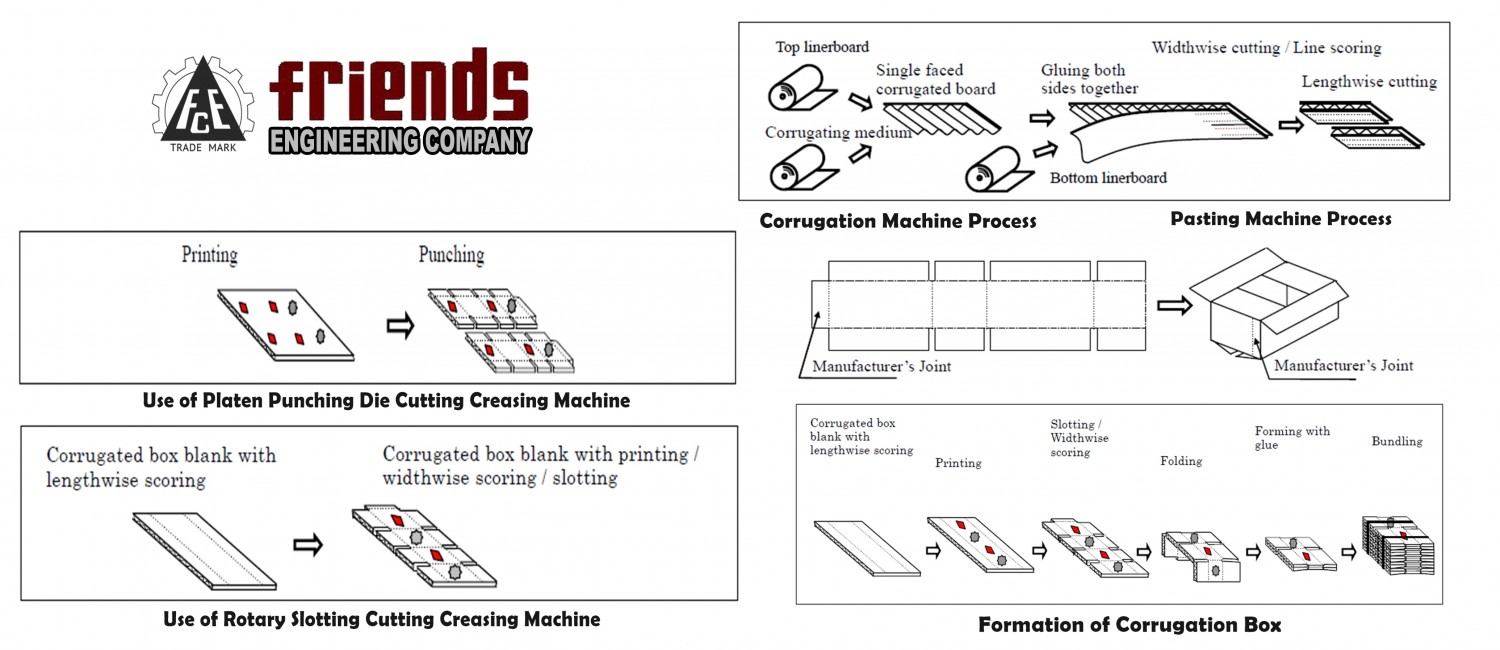

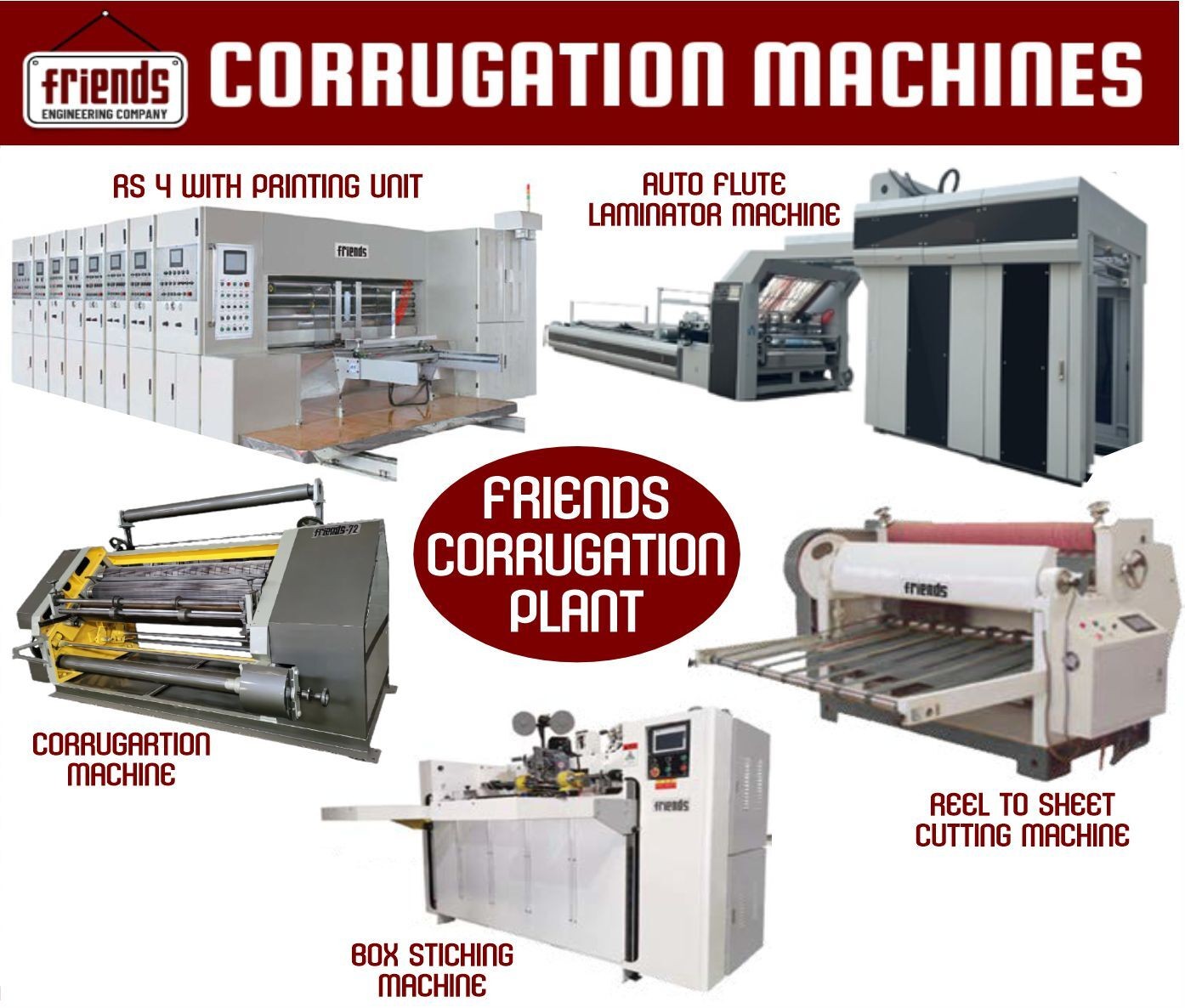

- Corrugated Boxes

Corrugated Boxes also known as Packaging / Carton Boxes. These are made from Kraft Paper (Brown Paper). Boxes used in the Packaging Industry for the products such as Fruits, Vegetables, Eggs, Beverages, Electronics, FMCG, etc.